The secret to success in the fast-paced commercial world of today is effective inventory management. It is essential to always have accurate inventory data for all sorts of businesses, from startups to multinational corporations. This is to satisfy customer demand, cut expenses, and keep the supply chain running smoothly. Real-time tracking through an Inventory Management System is one of the most significant developments in this field, which has completely changed the efficiency and accuracy of inventory.

What is Real-Time Tracking?

It is constant monitoring and updating of inventory data as it occurs. This technology tracks product movement, provides actionable insights into inventory status, and updates stock levels quickly. It uses systems like barcode scanning, RFID (Radio Frequency Identification), and cloud-based software. Instead of having to wait for manual updates, businesses can now know exactly what’s happening in their inventory at any given time.

Benefits of Real-Time Tracking for Inventory Accuracy

- Eliminating Human Error

Traditional inventory monitoring techniques often rely on manual entry, which is prone to human error. Real-time tracking eliminates these errors, which automates the data collection procedure. Every inventory movement is recorded by barcode scanners, RFID tags, and integrated software, removing the possibility of human error.

- Instant Data Updates

When a product is added, moved or sold, inventory levels are updated instantly using real-time tracking. Businesses are guaranteed to always have an updated view of their inventory because of this rapid access to data. The system instantly updates to reflect any changes made to objects, whether they are sold online, moved between locations, or received in the warehouse.

- Reduced Stockouts and Overstocking

One of the main problems with inventory management is maintaining a balance between supply and demand. Businesses can manage the right quantity of stock by using real-time tracking, which provides accurate insights into sales trends and inventory levels.

- Enhanced Supply Chain Efficiency

With real-time tracking, transparency is ensured across the whole supply chain. Companies are able to keep an eye on shipments or follow products as they move through the supply chain. By reducing delays and interruptions, this guarantees that goods are moved from suppliers to warehouses to customers in an efficient manner.

Businesses are managing their inventories in new ways because of real-time tracking, which improves operational accuracy, efficiency, and maximizes employee productivity. Through the elimination of human error, instantaneous updates, and real-time stock level visibility, businesses may enhance customer service, and make more informed purchase decisions. With the advancement of technology, it will become even more essential for businesses to maintain the ideal balance of inventories. This innovative and cost-effective tool helps businesses to stand out in the market and grow further.

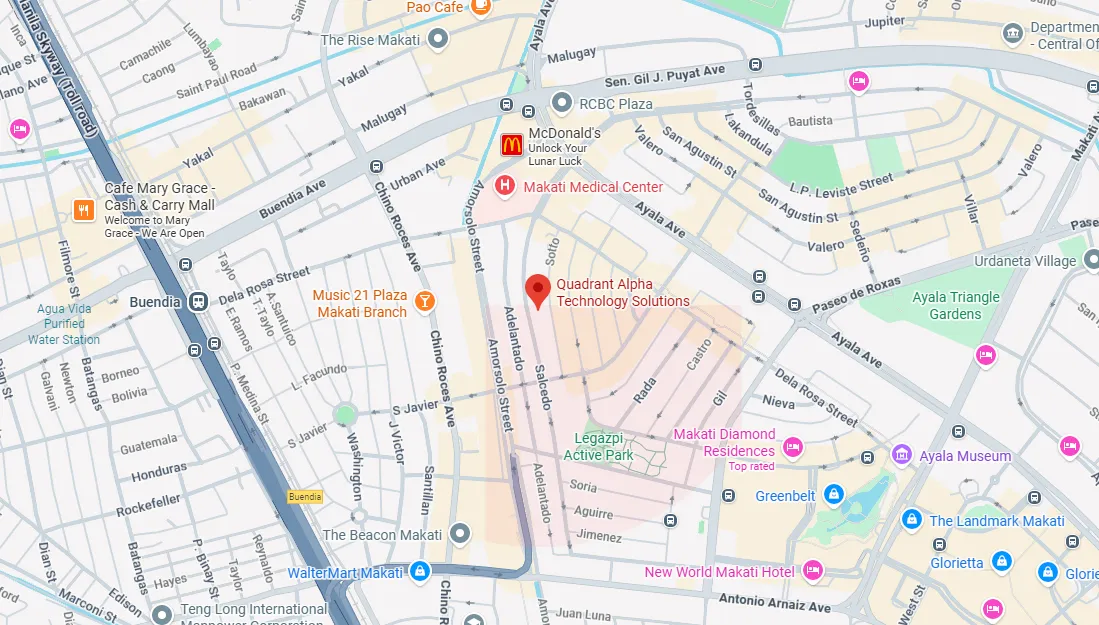

Quadrant Alpha Technology Solutions, Inc. is a local IT solutions provider with an expert and experienced team. Among the modules of the Inventory Management System that Quadrant Alpha offers are Warehouse Stock, Transfer Stock, Physical Count, Stock Adjustment, Order Release, Order Pickup, Transfer Damaged Inventory, and Damaged Warehouse. We ensure that businesses achieve their goals as we provide them highly reliable automated systems that they need. To learn more about how we can help, reach out to us and schedule a Demo!